What are the Key Points in Through Hole Slip Rings Selection?

Introduction

In many devices involving rotational motion, through-hole slip rings transmit electrical signals or power between their electrical components. However, how should we find the right slip ring? This article will give you a detailed introduction to the key points when selecting through-hole slip rings to help you make a decision.

1. Size

The through-hole size of a through-hole slip ring should be selected according to the diameter of the rotating shaft of the equipment. Generally, the through-hole diameter should be slightly larger than the diameter of the shaft to allow the shaft of the equipment to pass through the slip ring smoothly. For example, if the diameter of the rotating shaft of the equipment is 20 mm, then a slip ring with a through-hole diameter of 22 - 25 mm can be selected. We generally recommend reserving an installation gap of 0.5 - 3 mm. ByTune provides slip rings with an inner diameter of 3 to 500 mm, and the outer diameter can be provided according to requirements. They are very suitable for systems such as large cranes, rotary furnaces, machine tools, and other equipment.

2. Installation Methods

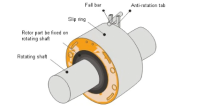

l Shaft Installation

The through-hole slip ring has a central through-hole structure. Shaft installation means installing by passing the shaft of the equipment through its central hole so that the slip ring can rotate with the shaft. And the diameter of the equipment shaft should be smaller than the inner diameter of the slip ring. This installation is mainly achieved through three methods: set screws, keyway connections, and spline connections.

l Flange Installation

Flange installation means that the through-hole slip ring is connected to the equipment through its own flange structure. The flange is a disc-shaped part with installation holes on it. During installation, we fix the flange of the slip ring on the corresponding installation plane of the equipment through connectors such as bolts. Large or rotating equipment with a large load often uses flange installation to increase stability, such as industrial robots.

3. Number of Circuits

In a through-hole slip ring, the number of circuits refers to the number of channels inside it that can independently transmit electrical signals or electrical energy, generally ranging from 2 to 100 circuits. Among them, slip rings with 2 - 10 circuits are suitable for small fan speed regulation, simple lighting rotating devices, etc. Such equipment has relatively low requirements for signal transmission, and the current of each circuit is generally 0.5 - 5A. While large industrial machine tools require slip rings with a large number of circuits (>30 circuits). They require the slip ring to transmit tool control signals while transmitting a large amount of current, which requires multiple independent transmission channels. In this case, ByTune can customize slip rings with a maximum of 300 circuits for you.

4. Component Materials

If the through-hole slip ring is mainly used for weak signal transmission, such as precision electronic instruments and communication equipment, we should choose gold and silver brushes. Because of its excellent conductivity, it can minimize signal loss. For heavy industrial equipment, graphite brush blocks are more suitable. Because it can be replaced individually and the cost is lower. Conductive rings are generally made of copper and copper alloys with coatings, just like we use PTFE to make insulating materials.

5. Protection Levels

l IP54: Slip rings of this level can prevent dust from entering and can resist partial splashing of water. It is suitable for indoor environments with a small amount of dust and occasional splashing of water, such as office copiers.

l IP58: This level indicates that the slip ring has good dustproof and waterproof immersion performance and can be immersed in water for a short time. Some rotating pan-tilts of outdoor monitoring equipment are often equipped with slip rings of this level. After these devices are immersed in water for a short time in heavy rain weather, they can still work normally.

l IP65: These slip rings completely prevent dust from intruding and can work normally when immersed in water for a short time (generally, the water depth is within 1 meter and the immersion time is 30 minutes). They are often used in rotating equipment in industrial environments where there may be more splashing water or dust.

l IP68: This is the highest protection level for slip rings. At this time, the slip ring can be immersed in water for a long time and work continuously in deep sea (water depth exceeding 100 meters) environments.

6. Rotational Speed

This refers to the number of revolutions per minute that the slip ring rotates, and the unit is usually revolutions per minute (rpm). It describes the speed at which the slip ring rotates around its central axis during the operation of the equipment. The rotational speed range of conventional through-hole slip rings is relatively large, generally between 100 and 800 revolutions per minute. They are suitable for some medium-sized rotating machinery, cable reels and other equipment. The rotational speed of ByTune's through-hole slip rings is between 300 and 1000 rpm, and we provide customized designs to make it reach a maximum of 5000 rpm.

7. Operating Temperature

Generally speaking, the operating temperature of through-hole slip rings is -20°C to 80°C. When outside this range, the insulating material of the slip ring will either become brittle or shrink at low temperatures, leading to poor contact, or expand at high temperatures and the insulation resistance will decrease.

ByTune's through-hole slip rings can be used in an environment of -20 - 120°C. This is because we use PTFE and precious metal alloy materials for its insulating and conductive parts, and also configure a highly sealed structural design. These slip rings can be used in metallurgical industry heating furnaces and maintain stable insulation resistance.

Summary

In short, when choosing through-hole slip rings, we need to consider factors such as the installation method of the equipment, the number of circuits, the conductive material, the IP rating, the rotation speed, the operating temperature, and the size. In this way, the slip ring can reliably transmit electrical signals and power in the equipment. ByTune hope this guide can help when you choose slip rings.

评论

发表评论